GFRP Rebar Products – Stronger, Smarter & Corrosion-Free

Introduction to GFRP Rebar

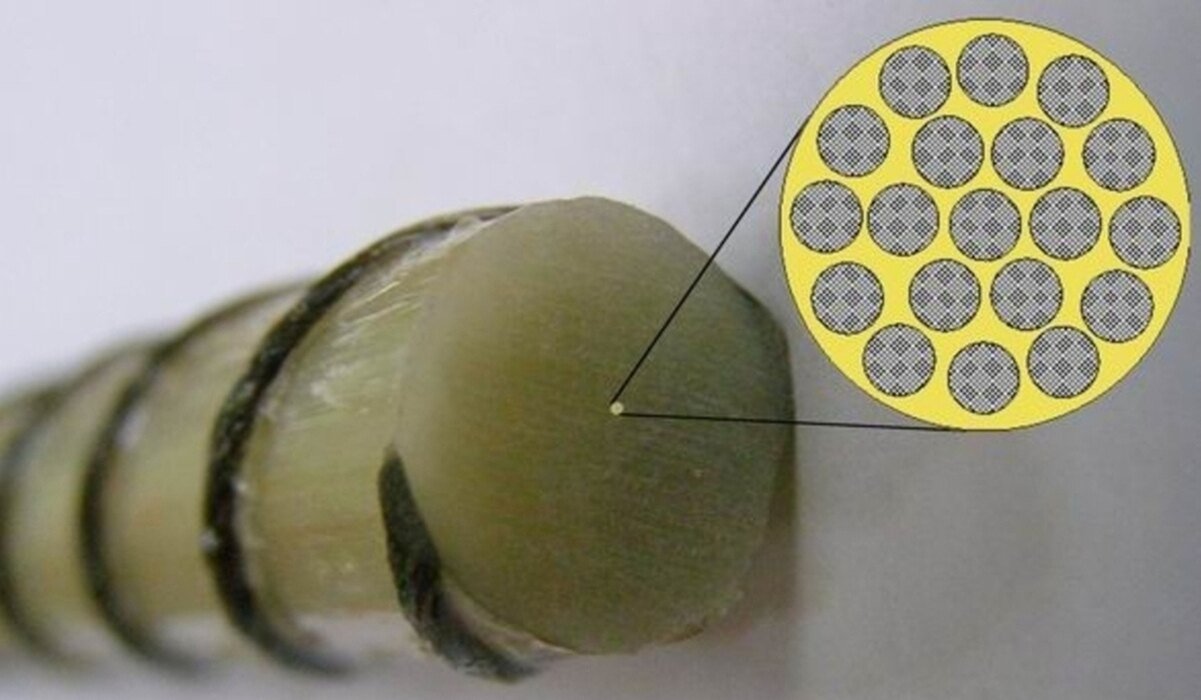

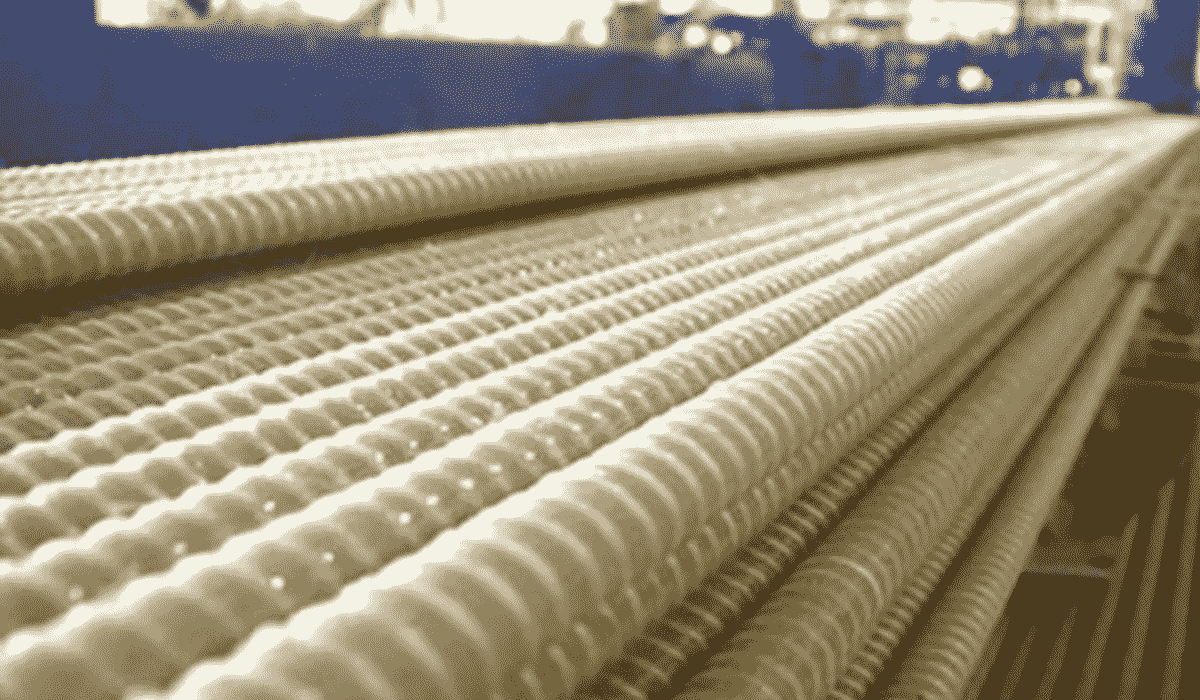

GFRP (Glass Fiber Reinforced Polymer) Rebar is an advanced reinforcement material engineered to replace conventional steel bars in concrete structures. Manufactured using high-strength glass fibers bonded with polymer resin, GFRP rebars provide unmatched durability, resistance to corrosion, and lightweight performance.

In today’s construction industry, where longevity, sustainability, and cost-effectiveness are top priorities, GFRP rebars are emerging as the next-generation alternative to steel reinforcement.

Key Features of GFRP Rebar

-

✅ Corrosion Resistant: Ideal for marine, coastal, and chemically aggressive environments.

-

✅ High Tensile Strength: Offers superior load-bearing capacity compared to steel.

-

✅ Lightweight & Easy Handling: Almost 75% lighter than steel, reducing transportation and installation costs.

-

✅ Non-Conductive & Non-Magnetic: Safe for electrical, medical, and sensitive structures.

-

✅ Extended Service Life: Designed for durability, reducing long-term maintenance costs.

-

✅ Environmentally Friendly: Supports sustainable construction with lower carbon footprint.

Applications of GFRP Rebar

-

Bridges & Flyovers – Resistant to de-icing salts and corrosion.

-

Marine Structures – Docks, ports, and piers exposed to seawater.

-

Roads & Highways – Long-lasting pavement reinforcement.

-

Industrial Plants – Chemical-resistant reinforcement for harsh conditions.

-

Residential & Commercial Buildings – Lightweight, durable reinforcement.

-

Tunnels & Power Plants – Non-conductive properties for safety.

GFRP Rebar vs. Steel Rebar – A Comparison

| Feature / Property | GFRP Rebar | Steel Rebar |

|---|---|---|

| Weight | 75% lighter, easy to transport & install | Heavy, increases handling cost |

| Corrosion Resistance | 100% corrosion-free | Susceptible to rust & corrosion |

| Tensile Strength | Higher than steel (2x in some cases) | Standard tensile strength |

| Conductivity | Non-conductive, non-magnetic | Conductive & magnetic |

| Durability | Long service life, minimal maintenance | Requires frequent repair & maintenance |

| Cost Over Time | Lower lifecycle cost, high ROI | Higher due to corrosion & repairs |

| Environmental Impact | Eco-friendly, supports sustainable projects | Higher carbon footprint |

Why Choose GFRP Rebar Over Steel?

While steel bars have been the traditional choice for decades, the limitations of steel—corrosion, weight, and high maintenance costs—make GFRP rebar the smarter choice for the future of construction. By switching to GFRP, contractors, engineers, and developers benefit from long-term savings, easier installation, and safer structures.

Richax Infracon – Your Trusted GFRP Rebar Supplier

At Richax Infracon, we provide premium-grade GFRP rebars that meet global quality standards. Our products are designed for performance, reliability, and sustainability, ensuring your projects stand strong for decades. Whether it’s highways, bridges, marine structures, or industrial facilities, Richax offers cutting-edge reinforcement solutions tailored to your needs.